13 / For installation, we use high-quality SKF bearings from Stage6.

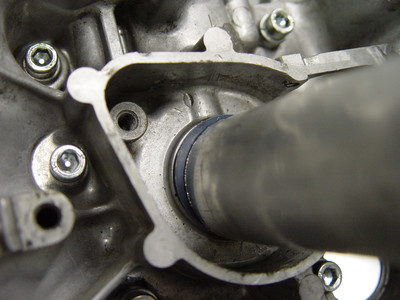

24 / Insert the retaining ring for the oil seal. The motor is now ready for installation of the cylinder.

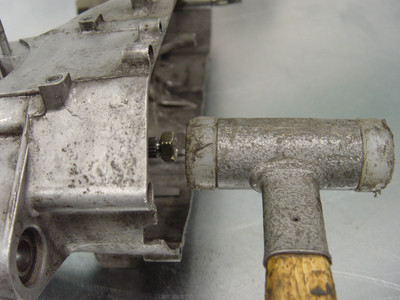

23 / Repeat the procedure on the ignition side. Again push the oil seal against the crankcase with a tube as far as it will go.

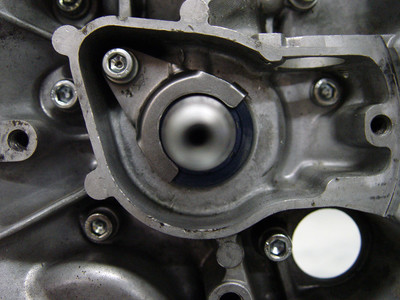

22 / Insert the retaining ring in the recess provided for this purpose.

21 / Insert the oil seal on the CVT side using a tube with matching diameter.

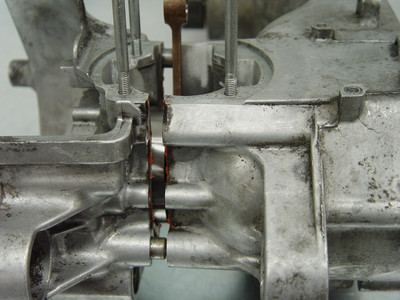

20 / Heat the inner ring of the bearing for a few seconds just like on the other side, then place the ignition-side crankcase half back onto the CVT-side crankcase half. It should be possible to insert the crankshaft effortlessly into the bearing. If this is not the case, tap it lightly, then screw in the 6 screws crosswise.

19 / Apply a strip of sealant to the sealing surface of the crankcase.

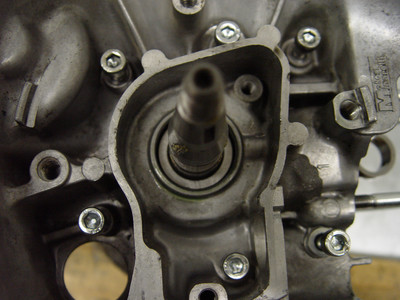

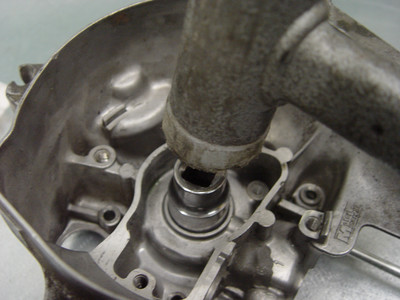

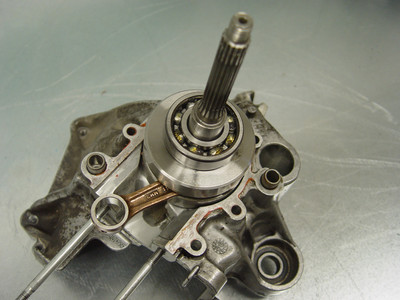

18 / Warm the inner ring of the bearing slightly (a few seconds) and insert the crankshaft immediately. It must be possible to insert the crankshaft without using any force. If it is not fully seated, tap it lightly with a hammer.

17 / Hold the bearing in your hand and immediately insert the bearing into the bearing seat after removing the heat gun. If the bearing seat has been heated long enough, the bearing should drop into the correct position on the bottom of the case without having to use any force. If the bearing gets stuck midway, you should lightly tap the outer ring of the bearing with a large enough socket.

16 / Use a heat gun to heat the bearing seats on the crankcase for 5 minutes.

15 / Lube the crankshaft bearings with grease, making sure that the grease gets between the inner and outer rings of the bearings.

14 / This set includes two C4 bearings and a pair of high quality oil seals.

01 / We will show you the removal and installation of a crankshaft using a Minarelli vertical engine. This tutorial can be applied to most scooter engines.

12 / Lightly sand the sealing surface if it is not clean and completely clean the inside of the crankcase to remove debris such as metal chips.

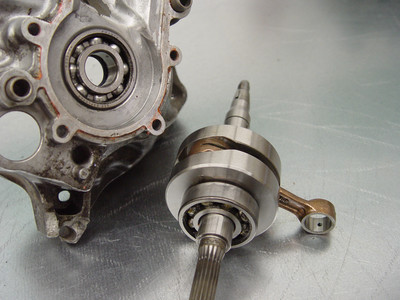

11 / The bearing can be easily removed.

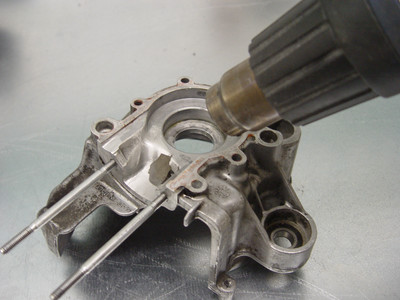

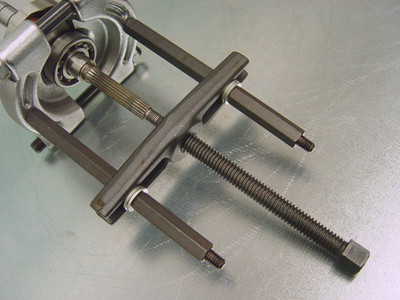

10 / Assemble the parts of the bearing puller as shown in the photo.

09 / In case the bearing is stuck on the crankshaft, we offer a bearing removal tool in all sizes in our store. With this kit, the bearing can be removed from the crankshaft in a few minutes without damaging the crankshaft or bearing.

08 / Remove the oil seals on the ignition side and the vario side with a screwdriver.

If the bearings are still stuck in the crankcase, use a socket of the same size as the oil seal seat and tap the bearings with a hammer to remove them.

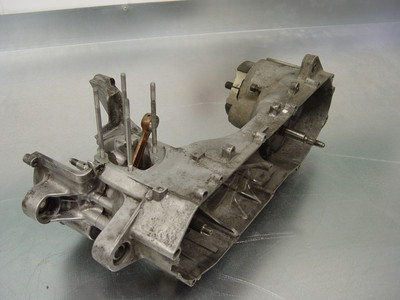

07 / You have successfully removed the crankshaft from the crankcase.

06 / Then tap the other side, again use a nut to protect the thread.

05 /...until you have split the halves nicely at the end. It will look like this.

04 / The crankcase halves are separating bit by bit ....

03 / Place a nut on the crankshaft and tap the nut with a soft-face hammer so as not to damage the crankshaft thread.

02 / First remove the retainer of the oil seal on the ignition side and loosen the 6 screws connecting the two halves of the crankcase (ignition side and CVT side).