Description

OEM quality torque drive cpi keeway

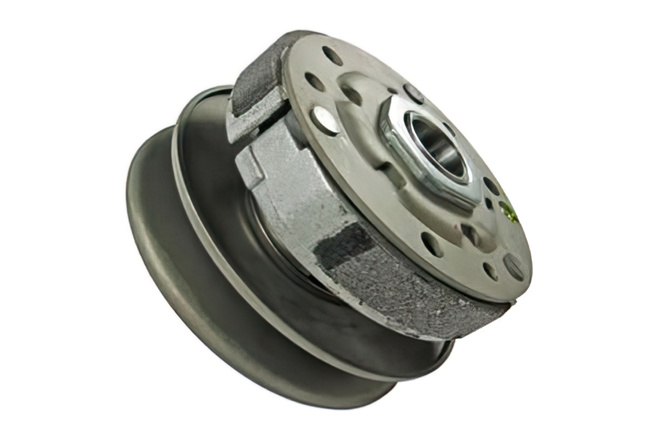

Pre-assembled rear pulley kit from Naraku. This set consists of rear pulley halves, torque spring, and 112 mm clutch. Quick and easy to install — no need to disassemble the variator unit.

Many snapped drive belts can be traced back to worn-out torque converters. Wear in this area often goes unnoticed until vibrations and uneven pulley movement put excessive stress on the belt, causing premature failure.

A cost-effective all-in-one solution for issues with clutch function or torque transfer.

Kit details – Naraku Torque Driver CPI

Complete standard rear pulley

Includes 112 mm clutch

Ready to install

rear pulley

The torque drive, also called secondary or driven pulley, is an integral part of the automatic transmission on scooters. It is the counterpart to the variator or front pulley and forms the rear drive unit. The rear pulley is located at the rear of the CVT housing and forms a unit with the clutch. As with the front pulley, there are also tuning versions of the rear pulley.

Working of a CVT transmission

The front and rear pulley (variator and torque driver) work together and are interdependent. At idle, the V-belt rides on its highest position on the rear pulley and on its lowest position on the front pulley. When you accelerate and engine speed increases, the drive pulley in front turns faster and faster. The centrifugal force pushes the variator weights outwards, opening the front pulley. This opening forces the V-belt to move further and further away from the axle shaft. As the belt cannot be stretched and is under tension, it has to move inwards on the opposite side of the CVT.

This increases the speed of the wheel and the scooter becomes faster. As soon as the V-belt has reached its maximum position on the front pulley and its lowest position in the rear pulley, the maximum drive ratio is reached. Now the scooter can reach maximum speed until the maximum gear ratio is reached.

When braking, the variator in front opens and the torque drive at the rear closes. The contra spring assists the closing movement of the driven pulley so that the V-belt returns to its original position.

Tuning torque driver

The performance of the torque drive depends heavily on the torque spring. In addition to the pitch and surface finishing, which can affect the speed of the belt movement, the hardness of the contra spring must be adapted to the engine power. In general, the more powerful the engine, the harder the spring.

Oversize torque drives are also available, usually as part of a complete drive kit with oversize front pulley and matching V-belt, which increase the working range of the drive ratio.

The highest quality torque converters offer various improvements - anti-wear treatment, reinforced bearings, special coating for more grip, guide bushes with different angles, improved heat dissipation ...., i.e. even more fine-tuning and options. The finer the adjustment and the better it is matched to the setup, the higher the performance.

| CVT Rear Pulley Naraku 110mm Keeway / Sym / Kymco GY6 139QMB/QMA | |

|---|---|

| Article no. | NK900.41 |

| EAN | 4250362411372 |

| Weight | 1,62 kg |

| Brand | Naraku |

| Product type | Torque drive |

| Clutch diameter | 112mm |