Moped clutch – automatic and simple

How a moped clutch works

Not all vintage mopeds are fitted with a variator, but they all have an automatic clutch. As on a motorcycle with a manual gearbox, its job is to disconnect or connect the engine and the transmission. The key difference is the centrifugal clutch, which engages automatically once a certain engine speed is reached.

Unlike a modern scooter, the clutch can work in two different ways:

- On mopeds with pedals, the clutch is driven directly by the crankshaft. The clutch works by centrifugal force and has clutch shoes that are held closed outwards by springs (which drive the clutch bell), but also a centre plate that is pushed out by balls. The centre plate mainly affects the take-off point. The shoes keep the clutch firmly engaged in operation.

As rpm increases, rotational speed rises, centrifugal force increases and the shoes open to bite into the bell, which then directly drives the V-belt. At idle, the belt therefore remains stationary. - On mopeds with kickstarter, the clutch sits on the rear pulley. Also designed as a centrifugal clutch, it is driven by the V-belt and opens as engine speed rises. It then drives the bell, which in turn drives the final drive gear. Unlike the system with the clutch at the front, the drive belt also rotates at idle here.

In both cases, no direct clutch action is needed to get things going.

ATTENTION: On some German models (Simson, Kreidler, ...), which are listed as mopeds, the clutch is not automatic. Here the operating principle is similar to a motorcycle clutch.

Moped clutch and engine tuning

As with any two-wheeler, the clutch needs to be adapted when power increases. On mopeds, this is not only about reliability, but also about the engagement point. A centrifugal clutch can be set up very precisely.

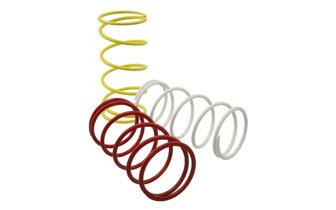

Since tuned engines usually deliver their peak performance at higher RPMs, it is especially beneficial to delay the engagement point. This ensures a snappier start and improved acceleration through the rev range. Depending on the system (clutch on the crankshaft or on the pulley), variation is possible via the balls, the star spring of the clutch disc, the clutch springs, or the weight of the clutch shoes.

Recommendations:

Depending on the tuning level (setup), it is not necessarily required to replace the complete clutch. However, setting it up is usually essential.

- Switching from the original exhaust to a performance exhaust? It can be worth trying to make the clutch lighter by removing balls or fitting several star springs (on the disc). Harder clutch springs are also available.

Example: Malossi spring set - Upgrading the moped with a more powerful cylinder? Then a reinforced and lighter clutch should be considered. It is more durable and engages at higher rpm.

→ Example: reinforced Motoforce disc, lightened Motoforce clutch shoes, Doppler sport clutch - Building a proper race engine with a very peaky power curve (high power in a narrow rpm range): A reinforced and at the same time lighter clutch is needed here, ideally as a complete kit. In this case, it is advisable to switch to a system on the rear pulley to reduce the weight on the crankshaft and make setup easier.

→ Example: Doppler ER2 system

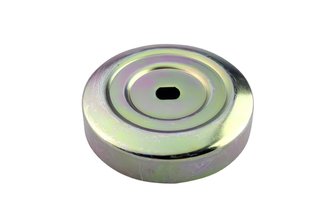

In addition, another clutch element is important: the clutch bell. The more powerful the engine, the hotter the clutch can get. The bell should therefore be matched accordingly, and a ventilated model should be chosen that fits the clutch.

Identifying faults and incorrect settings

Before discussing defects: on a stock engine, clutches are extremely long-lasting and almost never wear out. On tuned engines, they wear faster, especially if they are set up for very aggressive starts.

The main symptoms of wear are: the clutch slips, engagement is difficult, or it no longer engages at the right point (springs have weakened or stretched).

The main symptoms of incorrect setup are:

- The engine revs very high before the clutch bites, and take-off is very jerky: springs too stiff, or balls and shoes too light.

- The clutch engages while rpm is still too low, take-off is sluggish: springs too soft or stretched too much.

Moped clutches in our shop:

In our online shop, everything needed for servicing, setting up and improving the moped clutch can be found. Complete clutch kits are available, both in OEM quality and reinforced, as well as all individual components: springs, discs, bells, shoes, accessories and more. Parts from well-known manufacturers such as Malossi, Polini, Doppler, Motoforce are available, and of course for popular models such as MBK 51, Magnum Racing, Peugeot 103 SP / SPX / Vogue / RCX etc.

Clutch

Clutch Shoes extra light Peugeot 103

Clutch Bell Piaggio and Peugeot Red

Clutch Bell Piaggio and Peugeot Blue

Clutch Disc reinforced Peugeot 103

Clutch Bell Stage6 Wing Cooler 107mm Piaggio / Peugeot

Clutch + Bell Kit Stage6 Torque Control MK2 Piaggio / Peugeot

Clutch Bell Racing Stage6 R/T Wing Cooler Piaggio / Peugeot

Clutch Bell Stage6 R/T 460g Piaggio / Peugeot

Clutch Kit 107mm Malossi Fly Clutch Piaggio / Peugeot 50cc

Clutch Kit 107mm Malossi Delta Clutch Piaggio / Peugeot 50cc

Torque Spring Malossi Honda Dio / SFX

Clutch Shoes Malossi for engines without variator

Clutch Spring Set Malossi (engines without variator)

Clutch Spring Set Malossi (engines with variator)

Clutch Bell Malossi MHR Wing Bell Piaggio NRG / Typhoon

Clutch Bell Malossi Wing Bell 107mm Piaggio / Peugeot

Clutch Malossi Delta Clutch 107mm Piaggio

Torque Spring Seat Torsion Control Malossi Piaggio / Peugeot

Clutch Pulley Half Malossi 65mm Piaggio Ciao / PX

Clutch Pulley Half Malossi 70mm Piaggio Ciao / PX

Clutch Pulley Half (transmission) Malossi d=80mm Piaggio Ciao / PX

Torque Spring Malossi red Piaggio Si

Clutch Shoes Malossi Piaggio Ciao with CVT

Clutch Bell 93mm Malossi Wing Clutch Piaggio Ciao

CVT Rear Pulley Malossi Over Range Piaggio Si

Clutch Kit Malossi Fly Clutch Piaggio Bravo

Clutch Bell Malossi standard (107mm) Piaggio / Peugeot

Torsion Springs engine (x2) OEM quality MBK 51 / 88 / AV-7

Clutch Bell with vent holes Peugeot 103 SP / MVL / Vogue

Clutch Repair / Maintenance Kit Peugeot 103 MVL / SP /Vogue

Engine Tension Spring Doppler Soft white Peugeot 103 / MBK 51

Engine Tension Spring Medium Doppler yellow Peugeot 103 / MBK 51

Engine Tension Spring Hard Doppler red Peugeot 103 / MBK 51

Clutch Spring Solex

Clutch Shoes Piaggio Ciao / Vespa Ciao / Citta (w/o variator)

Clutch Pulley / Variator Pin MBK 51

Clutch Pulley OEM quality MBK 88 / 41 w/o variator

Clutch Bell MBK 51 / 41 / Club w. variator (ball weights)

Clutch Ring Peugeot 103 MVL / Vogue

Clutch Polini 3G Evolution Piaggio / Peugeot

Fixed front pulley Piaggio/Gilera after 1999

Clutch Bell Polini Speed Bell Vespa ET4 / LX 50cc / Peugeot

Variator Washer anti-friction Peugeot 103 MVL / SP / Vogue

Variator Washer (flanged) Peugeot 103 SP / MVL / Vogue

Variator Bearing Spacer Peugeot 103 MVL / SP / Vogue

Clutch Spring Washer (star) Peugeot 103 SP / MV / Vogue

Clutch Bell Peugeot 103 SP / MVL / Vogue

Clutch Shoes Peugeot 103 SP / MVL / Vogue (2x)

Clutch Disc Peugeot 103 SP / MVL / Vogue

Clutch Shoes Piaggio Ciao PX (x3 with springs)

Clutch Ball Peugeot 103 MVL / Vogue / SP

Clutch Circlips d=22mm MBK 51

Clutch Circlips d=15mm MBK 51

Clutch Shoes MBK 51 (2x)

Clutch Bell / Drum MBK 51 variator

Clutch Shoes Piaggio Ciao PX (2x)

Clutch complete Piaggio Ciao PX

Clutch Spring Peugeot 103 SPX / RCX grey x3

Clutch Spring Piaggio Ciao PX (1x)