The clutch – a key component in a scooter transmission

Function of a scooter clutch

As on a motorcycle with a manual transmission, the clutch’s job is to disconnect or connect the engine and the drivetrain. The difference: on a scooter, it is a centrifugal clutch. It engages automatically as soon as a certain engine speed is reached.

Several components work together: the crankshaft drives the variator, which moves the V-belt and the torque driver on which the clutch is mounted. The centrifugal clutch has clutch shoes that are held closed by springs. As RPM increases, rotational speed and centrifugal force increase - the shoes open and engage the clutch bell. This drives the transmission and the wheel. Direct operation of the clutch is therefore not required.

Scooter clutch and engine setup

Here too, as with a motorcycle: if performance increases, the clutch must be adapted accordingly. On a scooter, this is not only about reliability and preventing slip, but also about the engagement point. A centrifugal clutch can be adjusted very precisely.

The stiffness of the clutch springs directly impacts the clutch engagement point. Replacing or re-tuning them is therefore especially useful after upgrading to an engine setup designed for high RPM.

Recommendations:

Depending on the tuning level (setup), it is not necessarily required to replace the complete clutch. However, readjusting it is usually essential.

- Switching from a stock exhaust to a performance exhaust? Then stiffer springs are required.

- Upgrading your scooter with a more powerful cylinder? Then a reinforced clutch should be considered. It is more durable and less prone to slipping.

→ Example: Stage Sport Pro - Building a true racing engine with a very peaky powerband (lots of power, but only within a relatively narrow RPM range)? Then we recommend a clutch that is both reinforced and offers many adjustment options (spring preload, weights, etc.).

→ Example: Stage Racing Torque Control

In addition, another clutch component can be crucial: the bell. The more powerful the engine, the more likely the clutch is to heat up significantly. That is why the bell should also be chosen appropriately - ideally a ventilated model that matches the clutch.

Identifying defects and incorrect settings

A worn clutch or incorrect setting can often be identified without even having to open the clutch.

Typical wear symptoms include: the clutch slips, there is a strong smell of overheating (visible heat marks on the bell and damaged friction material on the shoes), engagement is difficult or no longer happens at the correct point (springs are fatigued and stretched).

Typical signs of incorrect adjustment are:

- The engine revs very high before the clutch engages, and off-the line acceleration is jerky: springs too stiff or too much preloaded.

- The clutch engages at too low an RPM, take-off is sluggish, and the scooter takes several seconds to build speed: springs too soft or not enough preloaded.

To make installation easier, there is a video tutorial on our channel.

Scooter clutches in our shop:

In our online shop you will find everything needed for maintenance, tuning, and optimization of the scooter clutch. We offer complete clutch kits in both OEM and reinforced versions, as well as all clutch components individually: springs, bell, accessories, etc. We carry parts from renowned manufacturers such as Malossi, Polini, Stage6, Motoforce as well as matching components for popular models such as MBK Booster and Nitro, Piaggio Zip and Typhoon, Peugeot Speedfight and Kisbee, and more.

Clutch

Clutch Springs Malossi blue super reinforced 2.0

Clutch Bell Malossi MHR Wing Bell 107mm Minarelli

Clutch Bell Malossi MHR Wing Bell Piaggio NRG / Typhoon

Clutch Bell Malossi Wing Bell 107mm Piaggio / Peugeot

Clutch Springs Malossi Piaggio / MBK / Peugeot Soft black

Clutch Springs Malossi Piaggio / MBK / Peugeot Medium white

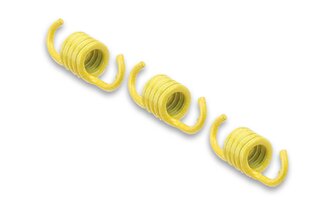

Clutch Springs Malossi Piaggio / Yamaha / Peugeot yellow

Clutch Springs Malossi Piaggio / MBK / Peugeot Extra Hard Yellow

Clutch Malossi Delta Clutch 107mm Piaggio

Clutch Malossi Delta Clutch 107mm Minarelli

Torque Spring Seat Torsion Control Malossi Piaggio / Peugeot

Torque Spring Seat Torsion Control Malossi Minarelli / Morini

Torque Spring Malossi white Peugeot Ludix / Speedfight 3

CVT Rear Pulley Malossi MHR Overrange MBK / Yamaha short

CVT Rear Pulley Malossi MHR Overrange Piaggio NRG / Typhoon after 1998

Rear Pulley Bearings Malossi Minarelli / Piaggio

Clutch Kit Malossi Fly Clutch Minarelli

Clutch Bell Malossi Wing Bell 107mm Minarelli

Clutch Bell Malossi standard (107mm) Yamaha Aerox / BW's

Clutch Bell Malossi standard (107mm) Piaggio / Peugeot

CVT Rear Pulley Malossi MHR Overrange Yamaha Aerox

CVT Rear Pulley Malossi d=34mm Yamaha Aerox / BW's

CVT Rear Pulley Malossi Piaggio NRG / Typhoon after 1998

CVT Rear Pulley Malossi 34.02mm Peugeot Speedfight / Trekker

CVT Rear Pulley Malossi MHR d=33mm Yamaha Aerox / BW's

CVT Rear Pulley Malossi Piaggio NRG / Typhoon before 1998

Clutch Malossi Delta Clutch d=107 Yamaha Aerox / BW's

Clutch Malossi Fly Clutch d=107 Yamaha Aerox / BW's

Clutch Malossi Fly Clutch Yamaha Aerox / BW's 100cc

Clutch Malossi Fly Clutch d=107 Piaggio / Peugeot

Clutch Malossi Fly Clutch d=105 Yamaha Aerox / BW's

Clutch Malossi Delta Clutch d=107 Piaggio / Peugeot

Clutch Malossi Delta Clutch 112mm CPI / Morini / Minarelli 100

Clutch Malossi Delta Clutch d=105 Yamaha Aerox / BW's

Clutch Springs Malossi MBK / Peugeot / Honda / Kymco 107mm

Clutch Springs Malossi Delta Clutch Racing Minarelli / Piaggio / Peugeot

Clutch Springs Malossi Fly/Delta Clutch Minarelli / Piaggio / Peugeot

Clutch Springs Malossi Racing Yamaha Aerox / BW's 100cc

Clutch Springs Malossi 105mm Yamaha Aerox / BW's

Clutch Springs Malossi Racing Morini

Clutch Springs Malossi Racing Piaggio / Yamaha / Peugeot

Rear Pulley Spacer Shims Malossi Minarelli

Clutch Springs 3x3 Polini Speed Clutch 3G

Clutch Bell Polini / Speed Bell 107mm Minarelli

Speed Clutch Polini 3G Minarelli

Washer clutch bell Vespa ET4/LX/S/GTS/GTSSuper/GTV/GT 60/GT 125-300cc

Clutch Springs Doppler SX86 red d=1.8mm

Clutch Springs Doppler SX86 white d=1.7mm

Clutch Bell Piaggio 50cc

Spring Seat f, torque spring (clutch side) Piaggio 50cc

Clutch / Rear Pulley Kit Honda Vision

Clutch Bell Naraku V.2 CNC 112mm CPI / Keeway / Generic

Clutch - original NRG / Runner

Clutch Polini 3G Evolution 107mm Minarelli

Clutch Polini 3G Evolution Piaggio / Peugeot

Clutch Springs Polini Speed Clutch Piaggio 1.7mm soft

Clutch springs Polini Speed Clutch Minarelli 107mm, d=1.7mm, green (medium)

Fixed front pulley Piaggio/Gilera after 1999

Rear Pulley, clutch + bell Minarelli before 1998 (105mm)